Double Sided Faux Leather Fabric Rolls for Placemat

Jul 17, 2024

Our Double Sided Faux Leather, made of PU/PVC/Silicone, unlike traditional fabric or woven, adds more factors for a placemat.

Compared to fabric or other materials for placemat, our double side faux leather has three advantages:

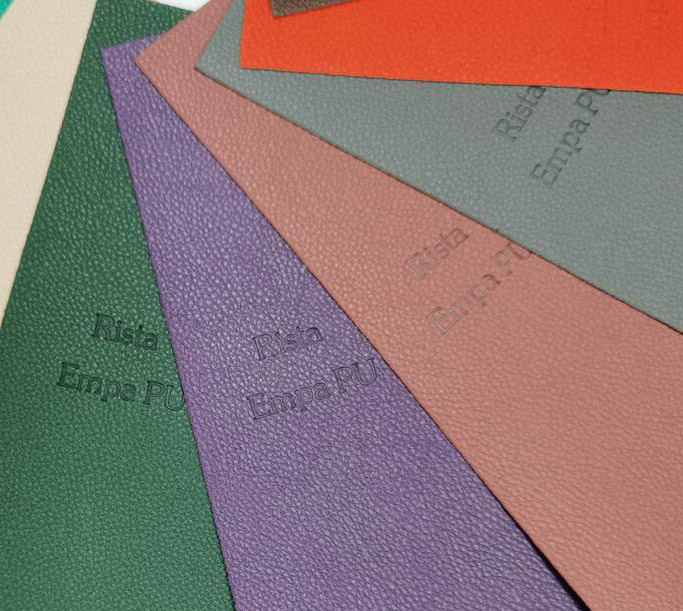

Broad Selection of Patterns and Colors: we can offer different designs and colors on each side. Double side same color or different colors, and you can do foil printing, digital printing on our faux leather, this allows you to get whatever in your mind to design a perfect placemat to various table settings

Easy to Clean: Maintaining our faux leather is a breeze. They are water-resistant and can be easily cleaned with a damp cloth or by rinsing with water. Even our silicone faux leather, has the function of oil resistance, stain resistance. Please note, machine washing is not recommended.

Versatile Use:Our Faux leather is designed perfectly for both indoor and outdoor settings, and you can use our materials to make placemats ideal for kitchen dining tables, coffee tables, restaurants, or business offices. They make excellent table decor for both festive occasions and everyday use.

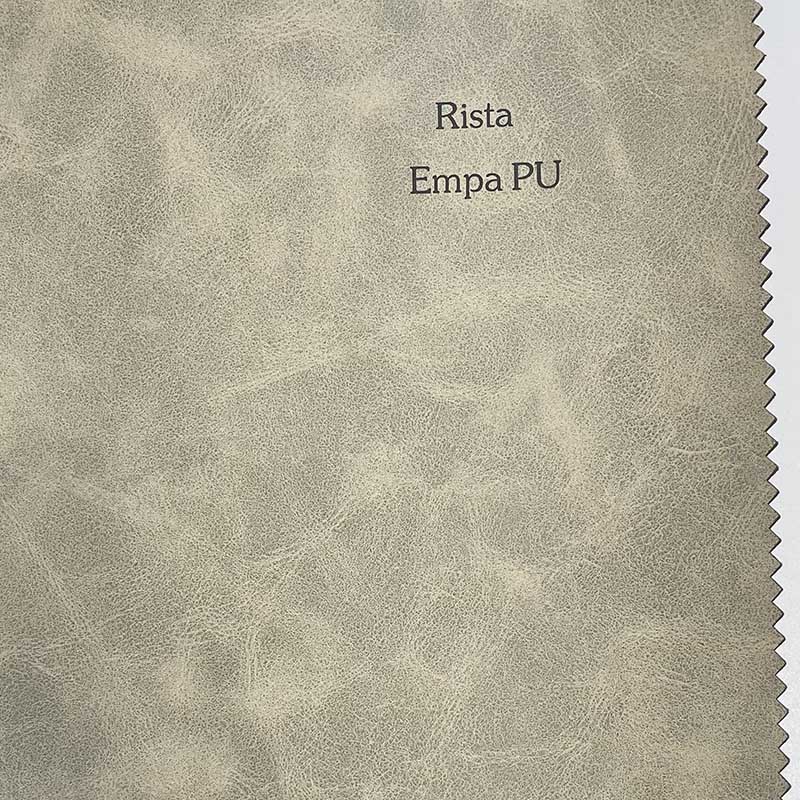

Hefei Rista New Materials Co., Ltd. specializes in Thermo PU Synthetic Leather, known for its excellent color change, texture, high physical properties, and eco-friendliness. Our high-quality products are widely used in jeans labels, menu covers, stationery, book covers, electronic covers, gift boxes, wine boxes, jewelry packaging, hotel desk supplies, and high-end hospitality.

We support various printing and stamping techniques for custom designs. Contact us today.

Email us: sales@ristapuleather.com

Read More